Oil Storage

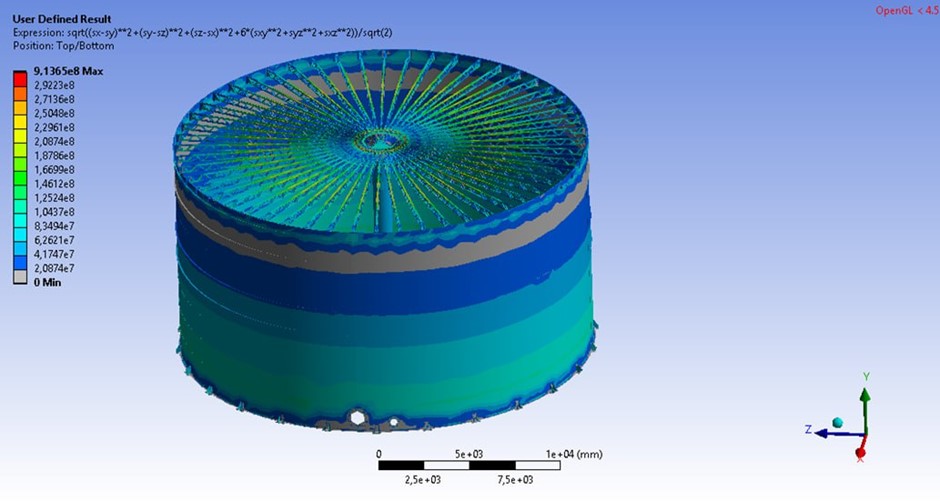

A client required a bolted and welded oil tank capable of withstanding seismic activity up to 8 on the EMS-98 scale. This project involved performing a thorough structural, modal, and spectral analysis to assess the effects of earthquake acceleration spectra specified in regulatory standards, as well as the impact of tank weight, fluid content, wind, and snow loads. CFD modeling was conducted to simulate wind load on the tank, producing a detailed pressure distribution map that was then incorporated into the structural analysis along with snow load, tank weight, and insulation parameters. Finite element analysis (FEA) evaluated local strength, stiffness, stability failure modes, and deformation under combined loads. A pre-stressed modal analysis determined natural modes and frequencies, followed by an earthquake response analysis using modal superposition to visualize the tank’s stress and strain distribution under all loads. Based on these calculations, the tank was designed, and constructed at the client’s site, and is now operational in a seismically active region.

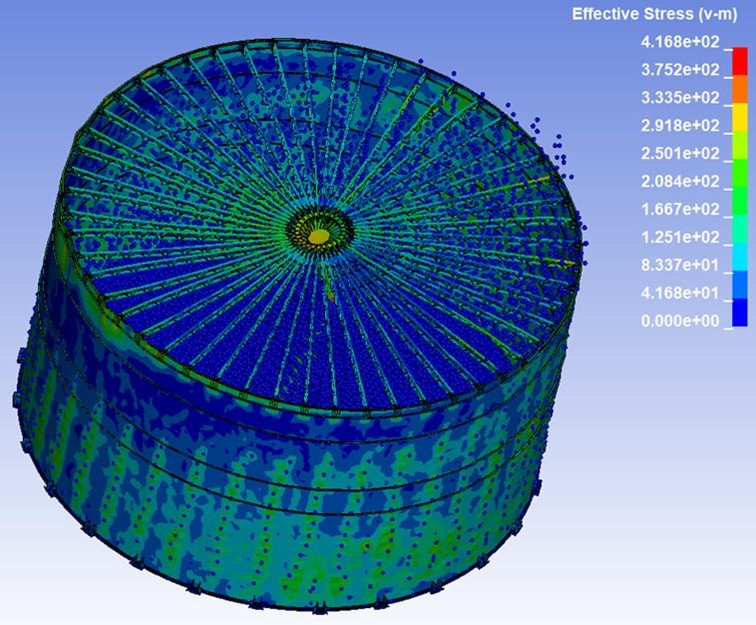

Wind loads were applied to the structural solver.

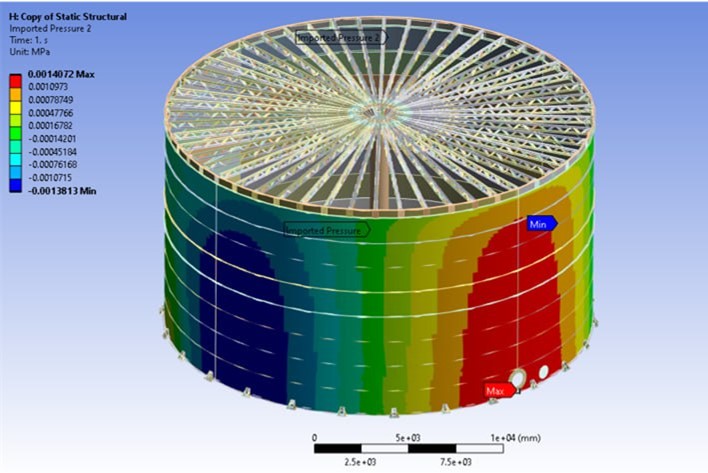

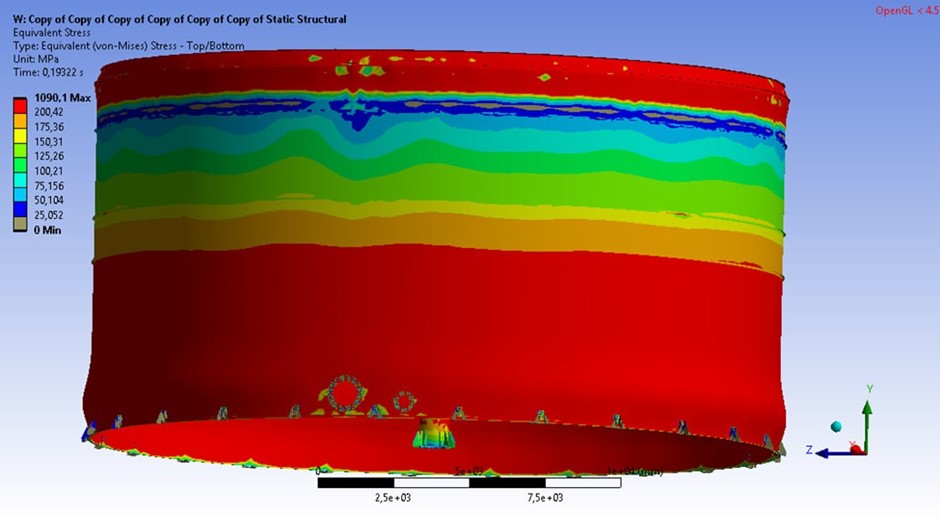

Stresses from weight loads in static analysis.

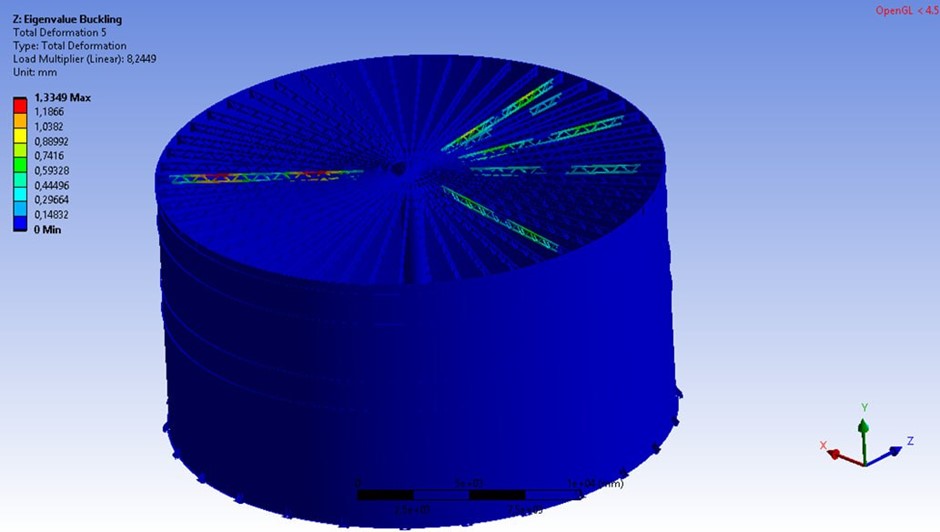

One of the buckling modes of the tank roof beams.

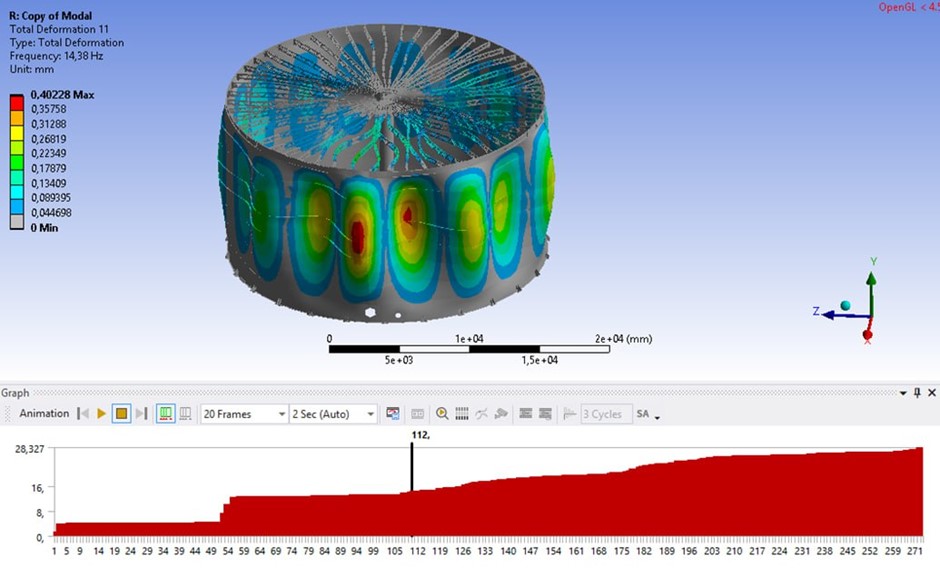

Buckling mode of the tank under the full combination of loads, increased by a factor of 4.

Mode of the roof beam's natural torsional-flexural vibrations.

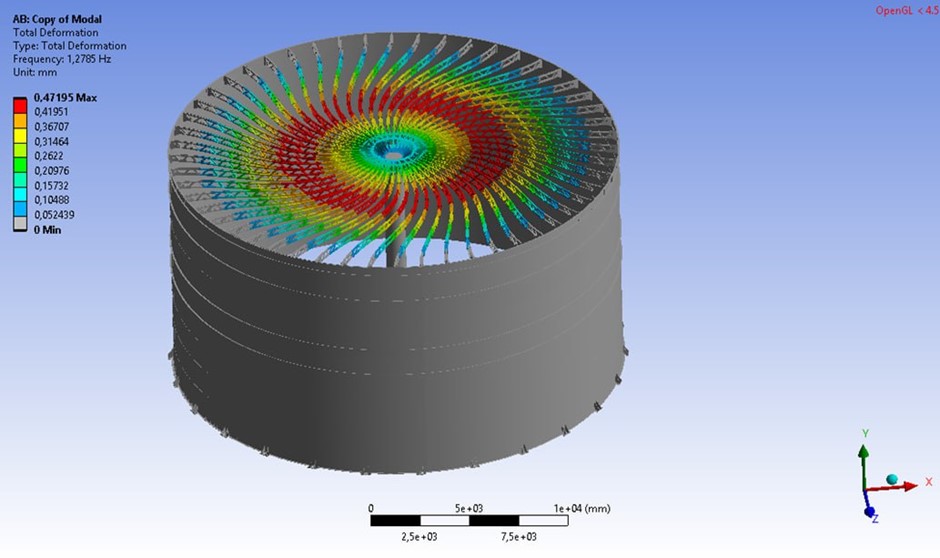

The first mode of the natural vibrations of the tank's side wall.

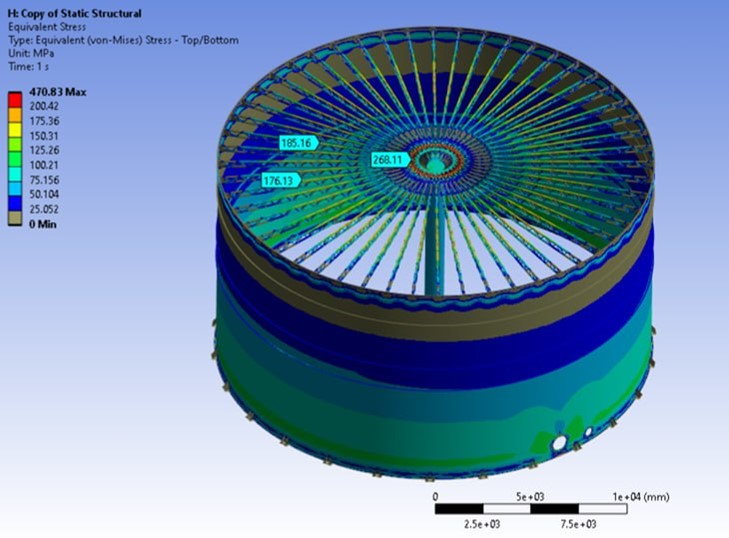

Von Mises equivalent stresses for the combined static and seismic loads.